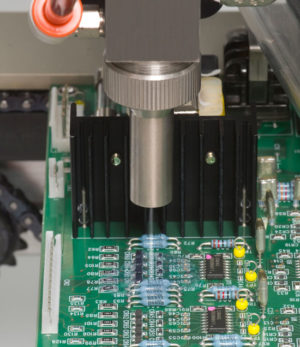

Conformal Coating

Connect Tech recognizes the harsh reality that many embedded systems find themselves in unusually hostile environments. When conformal coating is required to protect your electronics against substantial moisture, dust, chemicals or temperature extremes, we can help.

Connect Tech offers a range of conformal coating options, including: Acrylic Resins (AR), Epoxy Resins (ER), Polyurethane Resins (UR), Silicone Resins (SR)

Protect your circuitry when exposure to unique environmental circumstances is inevitable.

Conformal Coating Types

Acrylic Resins (AR)

Acrylic conformal coatings are easy to apply, and within minutes dry to the touch at room temperature. Acrylic resins do not shrink upon cure, and have a long working pot life. They have good fungus resistance as well as good resistance to humidity. Acrylic resins do dissolve easily in solvents, but this trait also leads to them being easy to rework. They do soften more quickly when compared to other chemistries when exposed to elevated temperatures, and also have a poor resistance to abrasion.

Epoxy Resins (ER)

Epoxy conformal coatings are typically available as two-part materials which begin to polymerize upon mixing. They can also be available as single a component material which can be cured with either elevated thermal exposure or with exposure to Ultraviolet (UV) light. These materials have good chemical, and abrasion resistance, with reasonable resistance to humidity. They are normally difficult to remove making rework difficult.

Polyurethane Resins (UR)

Polyurethane conformal coatings are one of the most resilient types of conformal coating. They are available as one or two-part materials. Polyurethanes offer very good solvent, corrosion and fungus resistance, and also offer a high dielectric strength.

Silicone Resins (SR)

Silicone conformal coatings are available in different forms, including heat-curing, moisture curing, and UV curing. They have a high resistance to corrosion, and solvents. They are also well-suited for high temperature applications. Silicones tend to be very flexible, but offer little adhesion, and abrasion resistance.

Thickness Requirements

| Type AR | Acrylic Resin | 0.03 – 0.13 mm (0.00118 – 0.00512 in) |

| Type ER | Epoxy Resin | 0.03 – 0.13 mm (0.00118 – 0.00512 in) |

| Type UR | Urethane Resin | 0.03 – 0.13 mm (0.00118 – 0.00512 in) |

| Type SR | Silicone Resin | 0.05 – 0.21 mm (0.00197 – 0.00827 in) |

| Type XY | Parylene Resin | 0.01 – 0.05 mm (0.000394 – 0.00197 in) |